Why a bike leg?

The World Health Organization estimates that 85-90% of amputees globally lack access to proper prosthetic care. This is due largely to insufficient infrastructure, finances, and/or local professionals.

Project Bike Leg aims to disrupt this statistic by providing a schema that details the process of making a functional below knee prosthesis from bicycle components.

If trained individuals can access this schema via the internet and successfully construct a prosthesis with on-hand materials, then maybe those millions of amputees who cannot otherwise access a traditional prosthesis may finally walk again.

Fabrication media to guide the process

Detailed instructions will guide the process of adequate fabrication to ensure a properly functioning and structurally sound device.

Reaching the masses via the internet.

The creation methods will be broadcast over the World Wide Web for reference to those who may be in need.

A detailed PDF/word doc for rapid translation.

Language barriers must be addressed with a physical document that details the process.

In The News

Collaboration with Michigan State University

Each semester, seniors in the Michigan State University mechanical engineering department will be constructing their own bike legs to hone the design. They will use the fabrication guides to assist them in the construction and implementation alongside Ben Hogan.

Read more here:

An innovative take on a traditional design with notable features:

Plantarflexion/ dorsiflexion, Toe in/Toe out, height adjustments possible

Modifiable socket with cable modulated compression

Lightweight design at around 3 Kg

Project vision

To broadcast an open-sourced below knee prosthesis design to allow for the creation of a functional, durable, and adjustable device with on-hand materials.

Meet the Team

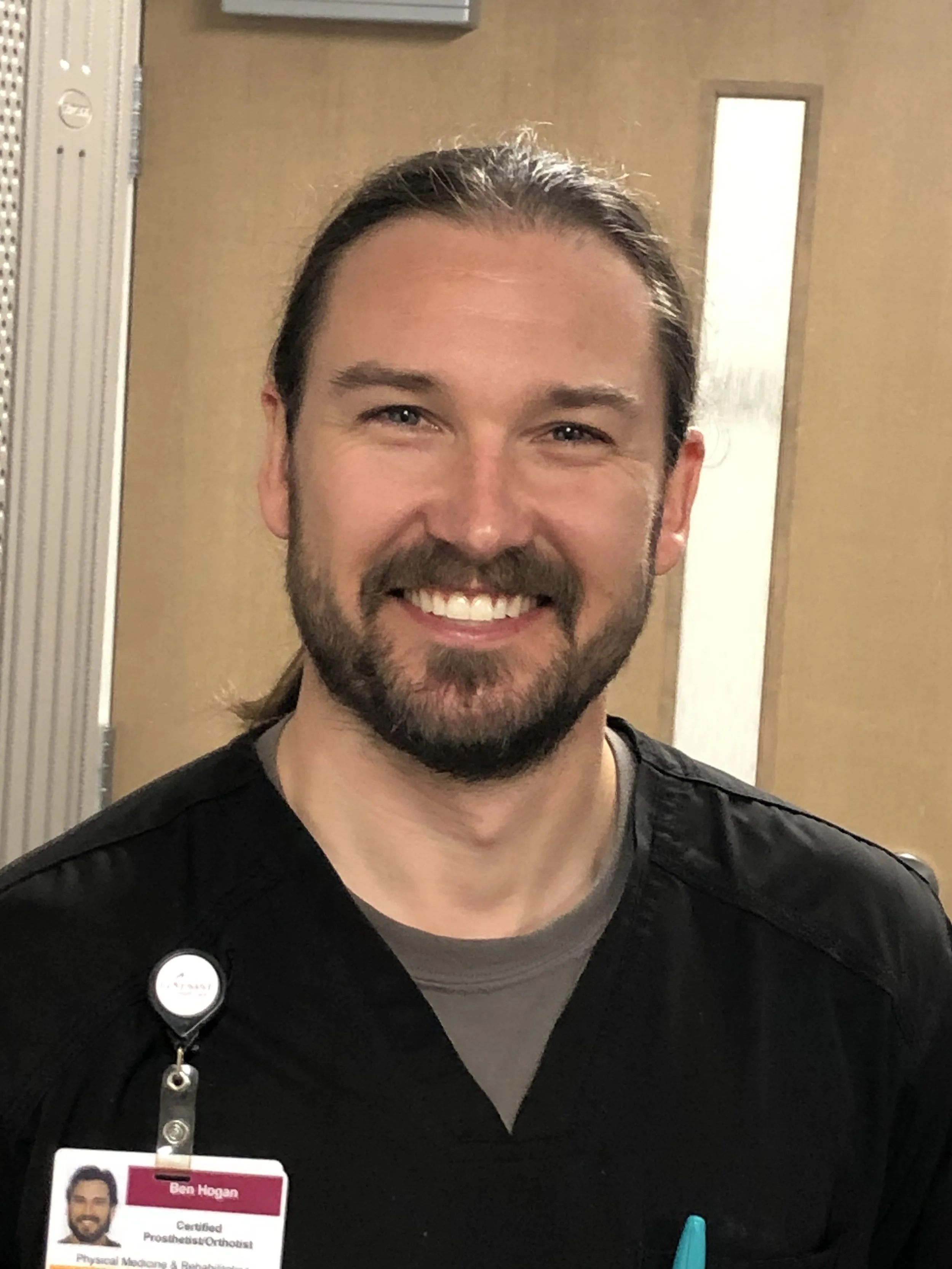

With 12 years of experience in prosthetics and 5 years of experience as a bicycle mechanic, Ben has applied his skillsets to create an innovative new method of providing prosthetic care to areas with limited resources.

At Mary Free Bed Hospital in Michigan (USA), Ben has honed his craft as a prosthetist working in a multidisciplinary team that includes physical therapists and physiatrists. He has also ventured on prosthetic relief trips to Guatemala with the Range of Motion Project to view firsthand the challenges facing the amputee population abroad.

.

-

Founder

Contact Us

Have questions or comments? Please reach out.